Heat resistance and …

Impregnating lacquers are used when the motor parts are fixedImpregless®︎

Impregnating lacquers are used when the motor parts are fixed, but there are many problems in the pollution factory environment of VOC and the waste time of the post heating treatment engineering. The Impregless series is the B project that can be coated with enameled wires to achieve low VOC without solvents and low molecular weight components. Moreover, the fixed time can be shortened by ohmic heating.

Impregless-HR is 200 degrees and so on. It can also be used in bad environment.

Characteristics:

1, high heat resistance, cars and so on can also be used at high temperatures.

2. Heated by electricity, it will be fixed for a very short time.

3, the friction coefficient is very hot, and the insertion resistance to the stator is very small.

4, evaporation without solvent and low molecular weight components will result in low VOC.

Use:

New energy vehicles, motors, appliances, mobile phones and other motor motors.

Performance:

1, the glass transition temperature can be adjusted between 150 and 180 degrees.

It can be fixed at 2, 180 degrees and 10 minutes.

3. The coefficient of static friction is 0.07.

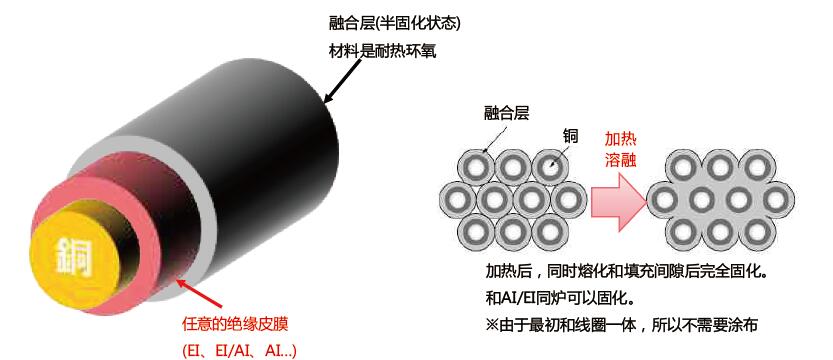

Structure of fusion line

Characteristic

Physical property contrast

Partners and end customers