High temperature and…

Ulmide®︎

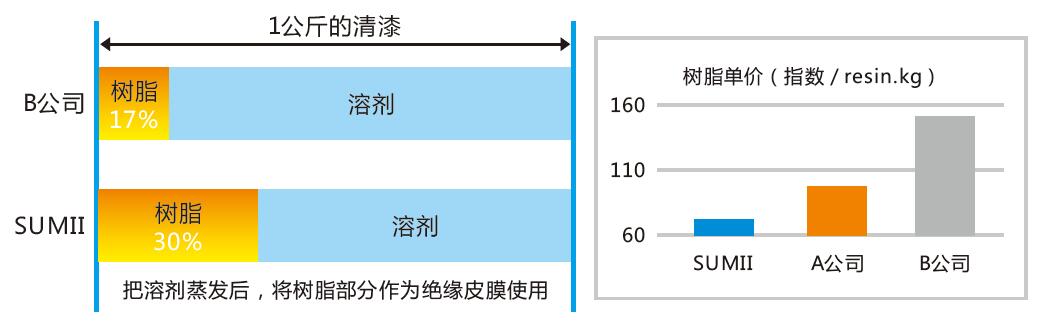

The Ulmide series is a fully aromatic polyimide material for chemical core technology in well drilling. Polyimide in well chemistry, the highest level of 30% of the world's highest level of solid content is reduced by the amount of solvent, so the cost can be reduced and environmental pollution can be reduced. According to the high viscosity technology of well chemistry, uniform coating thickness can also be achieved on the coils.

Ulmide is the highest solid content of 30% in the world. The solvent is reduced by solvent consumption, so the cost can be reduced and the environmental pollution is not.

Characteristics:

1, high glass transition temperature, inhibit the foaming of insulation layer when welding.

2. It has high heat resistance and maintains long-term electrical characteristics at high temperatures.

3, high toughness, even harsh processing will not rupture the film.

4. High quality electrical characteristics with high PDIV characteristics.

5, high solid content will reduce the number of coating, contribute to low solvent and reduce costs.

6. Any viscosity can be adjusted. The high viscosity type can improve the coating uniformity of the angle enameled wire, and the corners can also be well coated.

Use:

New energy vehicles, motors, appliances, mobile phones and other motor motors.

Performance:

1, the glass transition temperature is 350.

2, the heat resistance of 240 degrees C 280 degrees 2000hrs does not change the electrical characteristics.

3, the skin film stretching rate of more than 80%, patience will initially stretch 40%+ self bending;

4, dielectric constant 3.2, real 40 PDIV thickness of 1000Vp;

5, compared with the general 1.5 to 2 times solid content, the solvent can be reduced from 10 to 20%.

6, you can adjust the range of 2 to 30Pa. S.

High solid content

Reduce costs (reduce consumption / reduce environmental pollution)

Reduce coating times to increase productivity and reduce production costs.

high viscosity

The film is uniform to improve the insulation reliability, to increase the copper content in the motor to increase the output of the motor.

SUMII's high solid content, high viscosity PI lacquer technology, the world's leading technology.

Contrast the solid content of other companies

The concept of resin cost

Partners and end customers